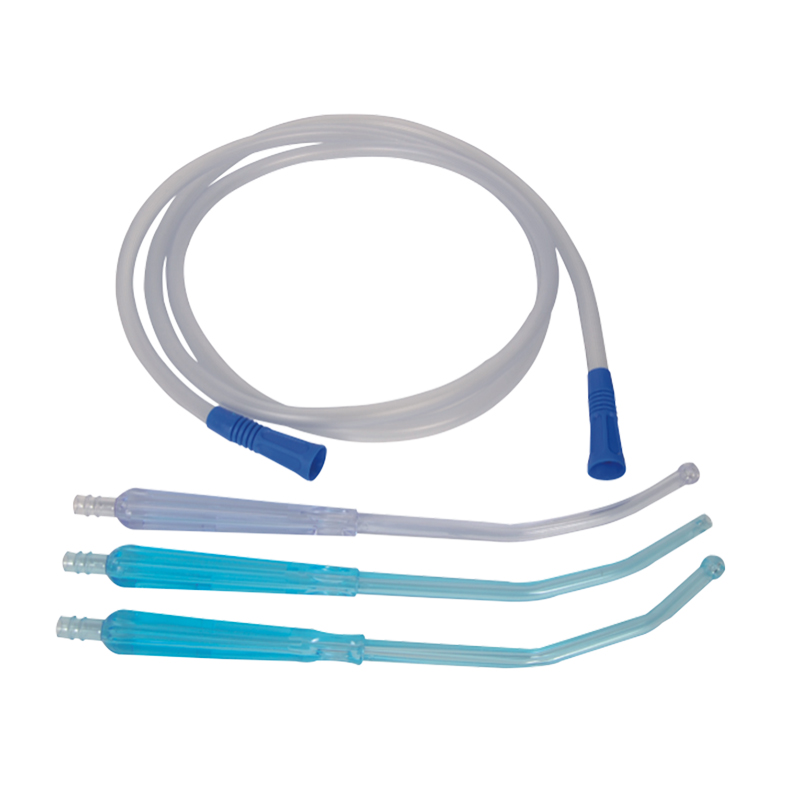

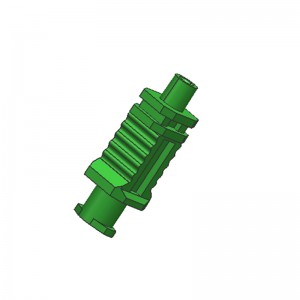

Lub Yankauer kov pwm yog cov cuab yeej tshwj xeeb siv hauv kev tsim khoom ntawm Yankauer tes. Lub Yankauer kov yog cov cuab yeej kho mob siv thaum lub sij hawm nqus cov dej los yog cov khib nyiab los ntawm tus neeg mob lub cev. Cov pwm yog siv los tsim cov khoom siv ntawm Yankauer suction device.Ntawm no yog qee qhov tseem ceeb ntawm Yankauer tuav pwm ua haujlwm li cas: Pwm Tsim: Cov pwm rau Yankauer kov yog tsim los tsim cov duab tshwj xeeb thiab cov yam ntxwv uas xav tau rau cov khoom siv. Nws feem ntau muaj ob lub halves uas haum ua ke, tsim cov kab noj hniav rau cov khoom molten yuav tsum tau txhaj rau hauv. Cov pwm feem ntau yog tsim los ntawm cov khoom siv ruaj khov, xws li hlau lossis txhuas, kom tiv taus qhov kub siab thiab kub cuam tshuam rau hauv cov txheej txheem molding.Material Txhaj Tshuaj: Thaum pwm tau teeb tsa, cov khoom siv thermoplastic, xws li PVC lossis polypropylene, yog rhuab kom txog thaum nws dhau los ua molten. Cov khoom molten yog ces txhaj rau hauv pwm kab noj hniav uas siv high-pressure txhaj molding tshuab. Cov khoom ntws los ntawm cov channel thiab cov rooj vag hauv pwm, sau cov kab noj hniav thiab noj cov duab ntawm Yankauer kov cov khoom. Cov txheej txheem txhaj tshuaj yog tswj hwm thiab meej kom ntseeg tau tias cov khoom tsim tau zoo sib xws thiab raug.Cooling, Solidification, thiab Ejection: Tom qab cov khoom raug txhaj, nws txias thiab solidifies hauv pwm. Kev ua kom txias tuaj yeem ua tiav los ntawm cov cua txias ua ke rau hauv pwm lossis los ntawm kev txav cov pwm mus rau hauv chav txias. Thaum cov khoom tau solidified, lub pwm qhib, thiab cov tiav Yankauer kov yog ejected. Ejection mechanisms, xws li ejector pins lossis cua siab, yog siv los ua kom muaj kev nyab xeeb thiab ua haujlwm zoo tshem tawm cov pwm los ntawm pwm. Cov kev tswj xyuas zoo yog feem ntau siv thoob plaws hauv cov txheej txheem tsim khoom kom ntseeg tau tias Yankauer tuav tau raws li qhov yuav tsum tau ua thiab ua raws li cov qauv kev kho mob. Qhov no suav nrog kev tshuaj xyuas cov pwm tsim, saib xyuas cov kev txhaj tshuaj, thiab ua cov kev soj ntsuam tom qab tsim khoom ntawm cov tes ua tiav kom paub tseeb tias lawv qhov zoo, kev ua haujlwm, thiab kev nyab xeeb.Zuag qhia tag nrho, Yankauer kov pwm ua kom muaj txiaj ntsig thiab meej ntawm Yankauer tes, uas yog cov khoom siv kho mob tseem ceeb siv hauv cov txheej txheem nqus. Cov pwm ua kom cov tes ua haujlwm tas li ua raws li qhov xav tau tshwj xeeb, ua tau raws li cov qauv kev kho mob, thiab muab kev ua haujlwm ruaj khov thaum lub sijhawm nqus cov txheej txheem.