Vaginal Speculum Pwm rau Kev Siv Kho Mob

Peb qhov chaw mos speculum pwm yog precision engineered rau kev kho mob daim ntaub ntawv, kom ntseeg tau tias cov khoom siv kho mob zoo. Nrog rau kev tsom mus rau qhov tseeb thiab kev ntseeg siab, cov pwm tsim los ua kom tau raws li cov qauv kev kho mob nruj thiab muab qhov tsim nyog precision rau kev tsim khoom ntawm qhov chaw mos speculum siv hauv kev kuaj mob.

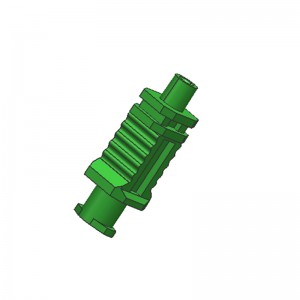

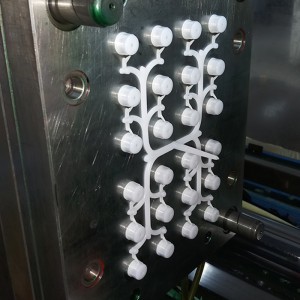

Qhov chaw mos speculum pwm yog ib hom pwm siv nyob rau hauv cov txheej txheem ntawm qhov chaw mos speculums. Vaginal speculums yog cov cuab yeej kho mob uas siv thaum kuaj gynecological los qhib thiab qhib cov phab ntsa ntawm qhov chaw mos. Cov pwm yog siv los tsim cov speculum los ntawm txhaj cov khoom tsim nyog rau hauv cov pwm kab noj hniav thiab tom qab ntawd tso cai rau nws kom khov thiab ua cov duab ntawm speculum.Ntawm no yog peb yam tseem ceeb ntawm yuav ua li cas lub qhov chaw mos pwm ua haujlwm: Pwm Tsim: Cov pwm rau qhov chaw mos qhov chaw mos feem ntau yog tsim los kom muaj ob sab uas tuaj ua ke los tsim cov kab noj hniav uas cov speculum yuav tsim. Cov pwm tsim muaj xws li cov yam ntxwv xws li cov duab thiab qhov loj ntawm cov speculum, lub tshuab kho qhov qhib lub kaum sab xis, thiab ib qho ntxiv nta xws li lub teeb pom kev zoo. Nws yog ib qho tseem ceeb uas yuav tsum muaj cov pwm zoo thiab tsim kom ntseeg tau tias cov speculum yog tsim nrog cov duab uas xav tau thiab kev ua haujlwm.Material Txhaj Tshuaj: Thaum pwm tau teeb tsa, cov khoom tsim nyog, feem ntau yog cov yas kho mob xws li polycarbonate, txhaj rau hauv pwm kab noj hniav. Cov khoom siv yog txhaj ntawm kev kub siab siv cov tshuab tshwj xeeb. Kev txhaj tshuaj xyuas kom meej tias cov khoom molten puv lub pwm kab noj hniav kom tiav, noj cov duab ntawm qhov chaw mos speculum. Cov cuab yeej siv thiab cov cuab yeej siv rau cov txheej txheem no yuav txawv nyob ntawm seb qhov kev xav tau tshwj xeeb thiab qhov ntsuas ntawm kev tsim khoom.Cooling, Solidification, thiab Ejection: Tom qab cov khoom raug txhaj, nws raug tso kom txias thiab khov rau hauv pwm. Kev ua kom txias tuaj yeem ua tiav los ntawm ntau txoj hauv kev, xws li cov phaj cua txias lossis cov cua txias. Thaum cov khoom tau solidified, cov pwm qhib, thiab cov khoom tiav ntawm qhov chaw mos raug tshem tawm. Lub ejection tuaj yeem yooj yim los ntawm cov txheej txheem xws li ejector pins lossis cua siab. Kev saib xyuas kom zoo yog noj thaum lub sij hawm ejection los xyuas kom meej cov molded speculum tsis puas.Zuag qhia tag nrho, lub paum speculum pwm yog ib qho tseem ceeb ntawm cov khoom ntawm qhov chaw mos speculum. Nws ua kom muaj txiaj ntsig zoo thiab ua raws li kev tsim khoom ntawm speculums nrog cov duab xav tau, kev ua haujlwm, thiab zoo. Kev tswj xyuas nruj nruj yog feem ntau siv thaum lub sijhawm tsim khoom kom ntseeg tau tias cov khoom kawg ua tau raws li qhov xav tau tshwj xeeb thiab ua raws li cov qauv kev kho mob.

| 1. R&D | Peb tau txais cov neeg siv khoom 3D kos duab lossis qauv nrog cov ntsiab lus xav tau |

| 2. Kev sib tham | Paub meej nrog cov neeg siv khoom paub meej txog: kab noj hniav, khiav, zoo, nqe, khoom siv, lub sijhawm xa khoom, cov khoom them nqi, thiab lwm yam. |

| 3.Tau qhov kev txiav txim | Raws li koj cov neeg siv khoom tsim lossis xaiv peb tus qauv tsim tawm tswv yim. |

| 4. Pwm | Ua ntej Peb xa pwm tsim rau cov neeg siv khoom pom zoo ua ntej Peb ua cov pwm thiab tom qab ntawd pib ntau lawm. |

| 5. Qauv | Yog tias thawj tus qauv tuaj tawm tsis txaus siab rau cov neeg siv khoom, peb hloov cov pwm thiab kom txog rau thaum cov neeg siv khoom txaus siab. |

| 6. Lub sijhawm khoom xa tuaj | 35-45 hnub |

| Lub npe tshuab | Ntim (pcs) | Lub teb chaws qub |

| CNC | 5 | Nyiv/Taiwan |

| EDM | 6 | Nyiv/China |

| EDM (Daim iav) | 2 | Nyiv |

| Hlau txiav (ceev) | 8 | Tuam Tshoj |

| Hlau txiav (nruab nrab) | 1 | Tuam Tshoj |

| Hlau txiav (slow) | 3 | Nyiv |

| Sib tsoo | 5 | Tuam Tshoj |

| Drilling | 10 | Tuam Tshoj |

| Lather | 3 | Tuam Tshoj |

| Milling | 2 | Tuam Tshoj |