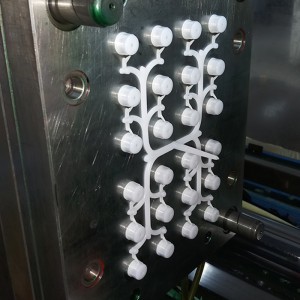

Lub stopcock pwm yog cov cuab yeej siv hauv cov txheej txheem tsim khoom los tsim cov stopcocks, uas yog cov li qub siv los tswj cov dej ntws los yog cov pa roj hauv ntau yam kev siv, xws li cov cuab yeej kho mob lossis cov cuab yeej kuaj. Nov yog peb txoj hauv kev ua haujlwm pwm stopcock: Pwm Tsim thiab Cavity Creation: Lub stopcock pwm yog tsim los tsim cov duab xav tau thiab kev ua haujlwm ntawm stopcock. Nws muaj ob los yog ntau tshaj ib nrab, feem ntau yog ua los ntawm hlau, uas tuaj ua ke los ua ib los yog ntau kab noj hniav uas cov khoom molten yog txhaj. Cov pwm tsim muaj xws li cov yam ntxwv tsim nyog, xws li inlet thiab qhov hluav taws xob ports, sealing nto, thiab kev tswj mechanisms, kom paub meej tias kev khiav hauj lwm ntawm lub stopcock.Molten Material Txhaj: Thaum cov pwm raug teeb tsa thiab kaw ruaj khov, cov khoom siv molten, feem ntau yog cov khoom siv thermoplastic lossis elastomeric, yog txhaj rau hauv cov kab noj hniav nyob rau hauv siab. Kev txhaj tshuaj yog ua los ntawm kev siv cov tshuab tshwj xeeb, xws li lub tshuab txhaj tshuaj molding, uas yuam cov khoom los ntawm cov kab thiab mus rau hauv pwm kab noj hniav. Cov khoom ntim cov kab noj hniav, noj cov duab ntawm qhov stopcock design.Cooling and Ejection: Tom qab cov khoom molten yog txhaj rau hauv pwm, nws yog sab laug kom txias thiab solidify. Kev ua kom txias tuaj yeem ua kom yooj yim los ntawm kev siv lub tshuab ua kom txias los ntawm pwm lossis siv cov phaj txias. Thaum cov khoom tau solidified, lub pwm qhib, thiab cov stopcock tiav lawm ejected los ntawm cov kab noj hniav. Kev tshem tawm tuaj yeem ua tiav los ntawm ntau yam txheej txheem, xws li ejector pins lossis cua siab. Kev tswj xyuas kev ua tau zoo, suav nrog kev tshuaj xyuas qhov tsis xws luag thiab qhov raug qhov tseeb, tuaj yeem ua nyob rau theem no kom ntseeg tau tias lub stopcock ua tau raws li qhov xav tau tshwj xeeb.Zuag qhia tag nrho, tsim kom zoo thiab ua tiav cov pwm pwm yog qhov tseem ceeb rau kev tsim cov khoom lag luam zoo uas ua haujlwm tau zoo. Cov pwm tso cai rau kev ua haujlwm zoo thiab zoo ib yam ntawm stopcocks, uas tau siv dav hauv ntau qhov kev lag luam rau kev tswj cov dej.