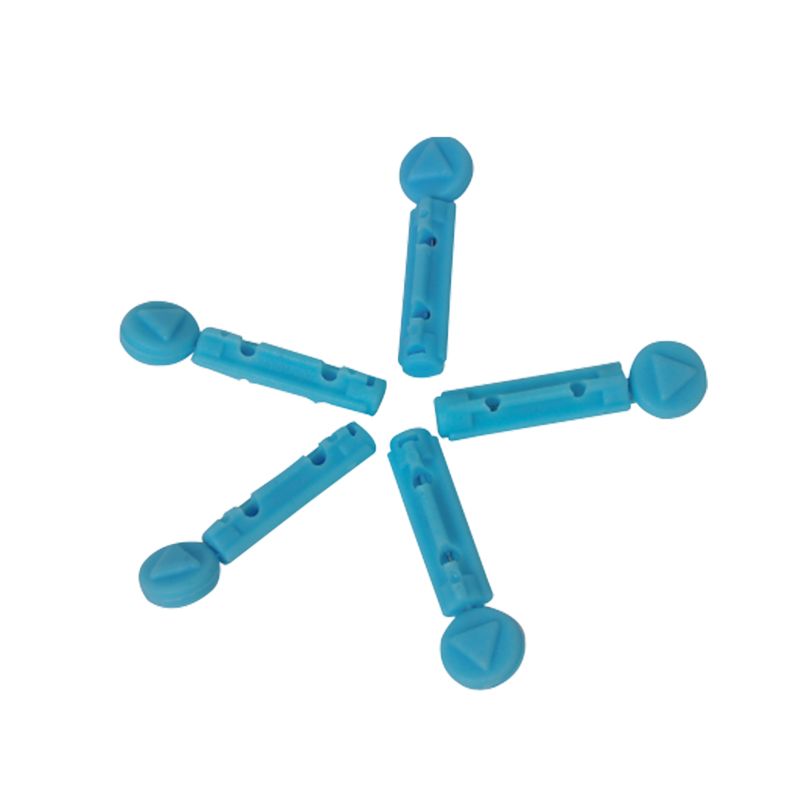

Lub lancet koob pwm yog cov cuab yeej siv hauv kev tsim khoom los tsim cov koob lancet, uas yog cov koob me me, cov koob ntse feem ntau siv rau kev kuaj mob xws li kuaj ntshav qabzib lossis kuaj ntshav rau ntau yam kev kuaj mob.Lub lancet koob pwm yog tsim los tsim cov duab uas xav tau thiab qhov loj ntawm rab koob lancet. Nws muaj ob lub halves, feem ntau yog ua los ntawm cov hlau, uas tuaj yeem ua ke los tsim cov kab noj hniav uas cov khoom siv molten raug txhaj.Cov pwm yog precision-engineered nrog cov ntsiab lus zoo sib xws thiab cov channel los xyuas kom zoo tsim cov koob lancet. Cov ntsiab lus no suav nrog lub koob lub ntsej muag zoo nkauj, bevel tsim, thiab rab koob ntsuas.Cov txheej txheem kev tsim khoom feem ntau yog txhaj cov khoom siv molten, xws li cov hlau tsis muaj steel lossis cov yas kho mob, rau hauv cov pwm kab noj hniav. Thaum txias thiab khov kho, cov pwm qhib, thiab cov koob lancet tiav lawm raug tshem tawm. Kev tswj xyuas kev ua tau zoo yog siv thoob plaws hauv cov txheej txheem tsim khoom kom ntseeg tau tias cov koob lancet ua tau raws li qhov yuav tsum tau ua thiab cov qauv kev nyab xeeb thiab kev ua haujlwm. Qhov no suav nrog kev tshuaj xyuas cov pwm rau txhua qhov teeb meem lossis qhov tsis sib xws uas yuav cuam tshuam rau qhov zoo ntawm cov koob txhaj tshuaj.Zuag qhia tag nrho, lancet koob pwm plays lub luag haujlwm tseem ceeb hauv kev tsim cov koob lancet zoo thiab meej, uas yog cov cuab yeej tseem ceeb hauv ntau cov txheej txheem kho mob.